What is a Work Order? Ending Chaos in Manufacturing

A work order is the most critical management tool on the production floor. This document ensures the process runs without errors and directly determines your business efficiency. But what exactly is a work order, and why must manufacturers digitize this process immediately?

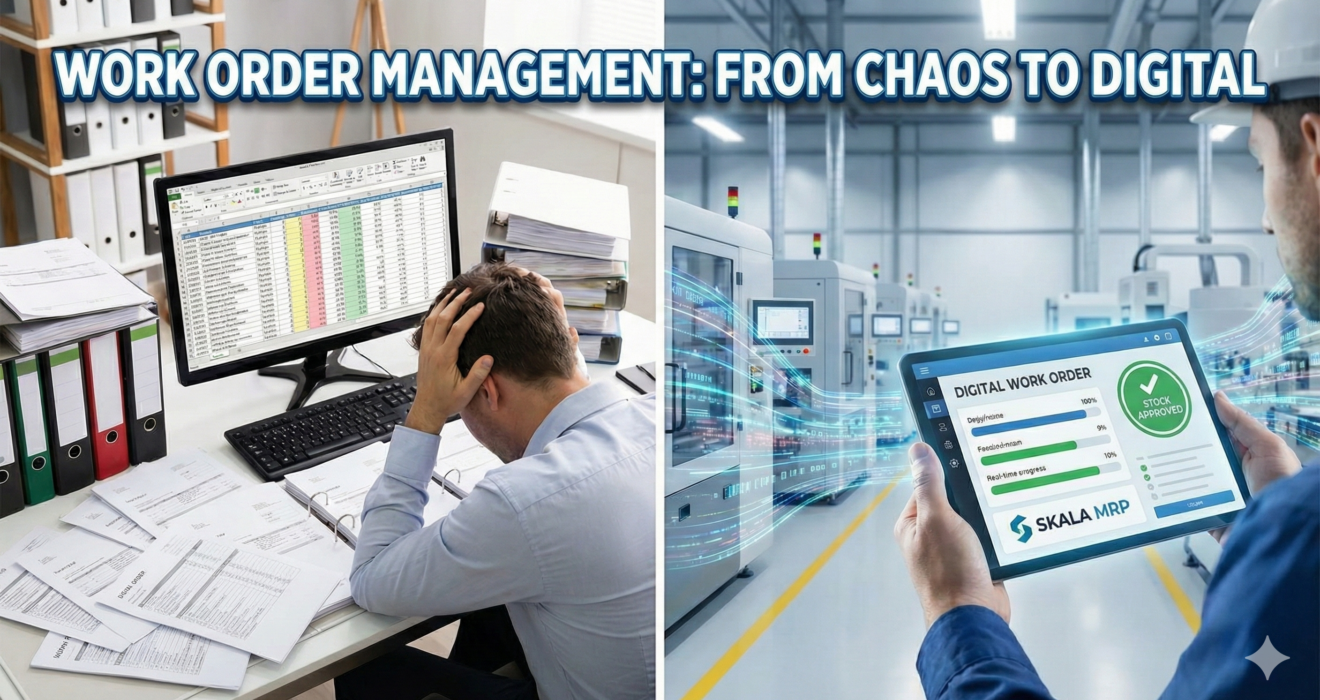

If you still manage your production processes using paper forms or Excel spreadsheets, you likely incur invisible costs. In this article, we explore the cornerstone of production management and how digitizing it saves your business from chaos.

What Exactly is a Work Order?

In its simplest definition, a work order is an authorization document containing all necessary instructions for production. It tells operators or relevant departments exactly “what to do.”

This document acts as the production roadmap and clarifies the following:

- Product: What are we producing? (Product Code and Name)

- Quantity: How much do we need?

- Timeline: When is the due date?

- Resources: Which recipe, machine, and operator will we use?

If you write these answers on a piece of paper and lose that form, production stops. That is precisely why the work order tracking process remains vital. a piece of paper and that form gets lost, production stops.

The Process of Creating an Effective Work Order

A correctly structured instruction leaves no room for questions on the floor. To create an effective work order process, follow these steps:

- Order Confirmation: The customer order enters the system.

- Stock Check: Do we have the necessary raw material in the warehouse?

- Planning: Which machine is free? Which operator will run the job?

- Issuing: You transmit the document to the production floor.

Executing these steps according to standards aligns your business with ISO 9001 quality management principles.

The Hidden Costs of Excel and Paper

Many businesses still try to manage their work order processes in spreadsheets, despite the call for digitalization. However, manual tracking creates significant problems:

- Outdated Data: By the time you update the Excel file, the team might have already finished the production or made a mistake.

- Communication Breakdown: The production manager must go down to the floor to physically find that specific paper.

- Material Blindness: You open a work order, but only realize the raw material is out of stock when production is about to start.

Digital Work Order Management with Skala MRP

The best way to end the chaos is to digitize the process. In line with the vision of Industry 4.0, Skala MRP manufacturing accounting software allows you to manage all processes on a single screen.

How does digital management help you?

- Instant Traceability: The order you enter into the system instantly falls onto the operator’s tablet. You no longer need to carry paper.

- Automatic Reservation: When you create a digital order, the system automatically reserves the raw materials in the recipe.

- True Costing: When operators complete the process, the system calculates the exact time and material used. You see your real cost, not an estimate.

Manage the System, Not the Chaos

A work order is not just a command; it is a process that determines your profitability. Take a step today to eliminate the mess created by Excel spreadsheets.

Digitize your processes with Skala MRP and increase your efficiency.

Contact us to see our digital solutions tailored to your business.

🌐 Website:https://www.skalasuite.com/